|

Rick Akkerman I am a research intern at the Max Planck Institute for Intelligent Systems (MPI-IS) in Tübingen, advised by Dimitris Tzionas, Victoria Fernández Abrevaya and Haiwen Feng. Currently, I work on the intersection of human-object interactions and video diffusion models. I recently received my MSc degree in Artificial Intelligence from the University of Amsterdam on the same topic. Before my master’s, I received my BSc degree in Technology & Liberal Arts and Sciences from the University of Twente, where I worked on federated learning. During my master’s, I worked at the Innovation Center for Artificial Intelligence under Esther Smit and Maarten de Rijke: helping organize events centered around AI and their ability to help us achieve the European Commission's Sustainable Development Goals. |

|

ResearchI am passionate about computer vision, deep learning, generative AI and image processing. My main research interest is in 3D-consistent image and video generation. |

|

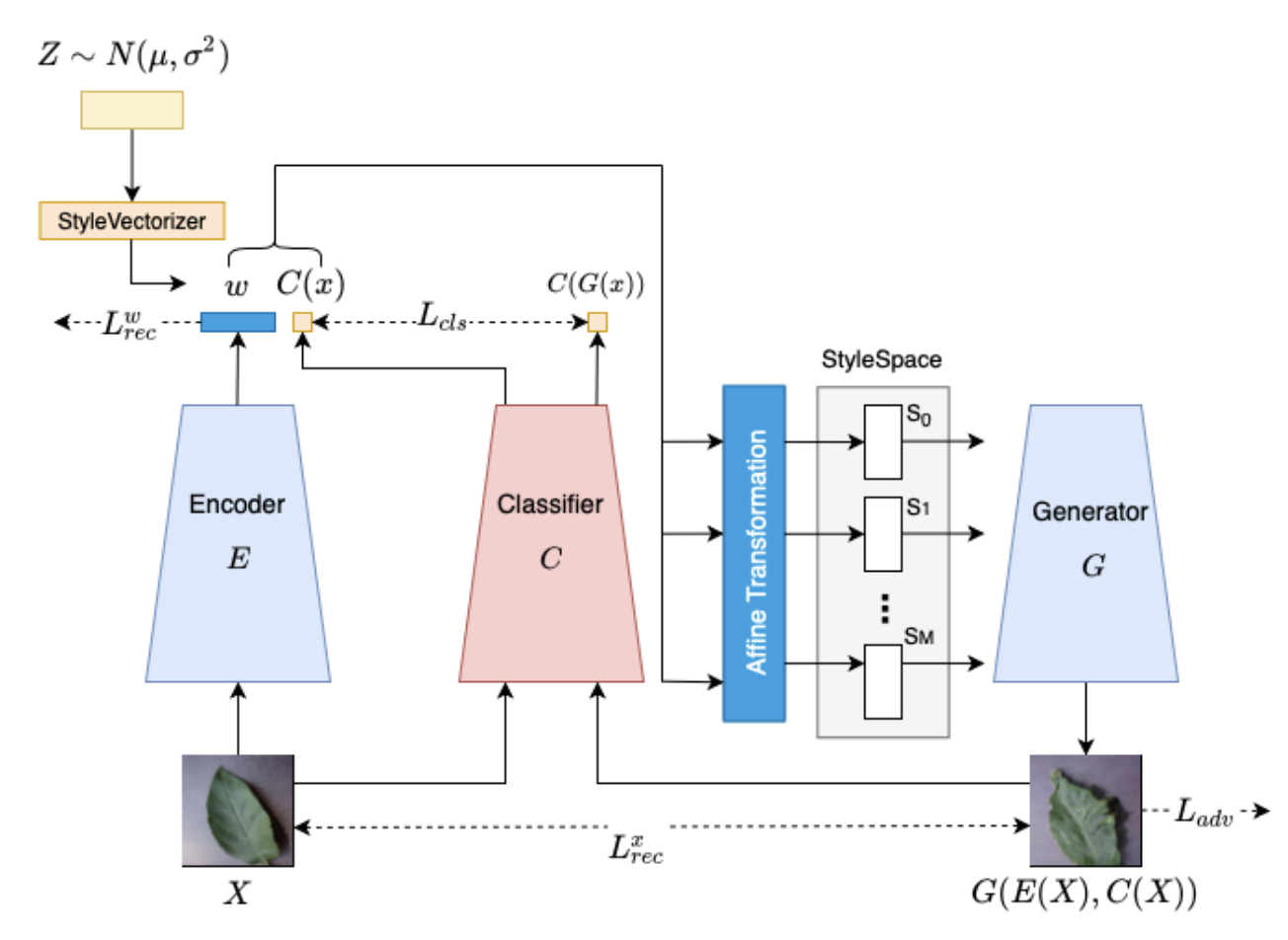

[Re] Explaining in Style: Training a GAN to explain a classifier in StyleSpace

Noah van der Vleuten, Tadija Radusinović, Rick Akkerman, Meilina Reksoprodjo Journal: Rescience C, 2022 Publication | Code | NeurIPS Poster By incorporating a classifier into StyleGAN’s training process, StylEx develops a classifier-specific StyleSpace. Within this space we can find disentangled attributes that can be used to generate counterfactual images that flip the classifier’s decision. With it's code unavailable, we reproduced Stylex from scratch. During this project we had frequent contact with the authors Lang et al. for clarifications on training details and we presented the results at NeurIPS 2022. |

Projects |

|

Leakage detection in sealed laundry pod containers using thermal imaging

Rick Akkerman, Niels Beukers, Niels Koerssen, Akash Ravi Prame Company: Tembo, 2021 The dataset also served as the basis of Akash's master thesis After coming off the production line, some laundry pods start leaking on the bottom of an already sealed container, calling for non-destructive quality inspection. The plastic of the container conducts heat faster to the liquid than to air, which means we can measure a thermal difference between clean and leaked-on areas when heated. Using a cobot, ceramic heater and a high-end thermal camera, we collect a dataset of consistent, uniformly heated and high quality thermal images. Using this dataset, I trained an image classification system using ResNet and achieved an accuracy of 92%. |